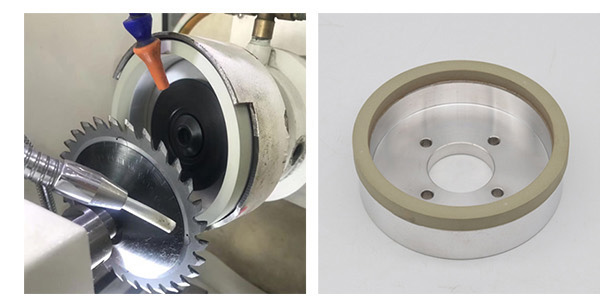

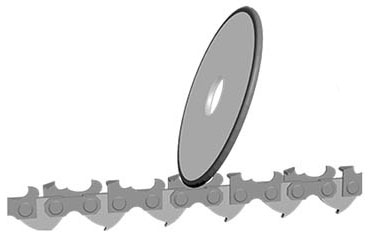

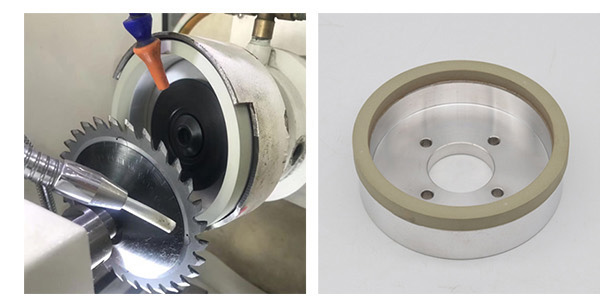

- High quality ceramic diamond grinding wheel for rough and fine grinding PCB circuit board V-Cut knife

- Bola Rong can provide high-quality ceramic diamond grinding wheels for rough and fine grinding of PCB circuit boards, V-Cut knives, woodworking saw blades and other pcd tools. Ceramic diamond grinding wheel has better mechanical strength, long service life, fast cutting speed, good heat resistance, sharp cutting, high grinding efficiency, and it is not easy to accumulate heat during the grinding process, and it is not easy to cause blockage. It perfectly solves the problem of low efficiency, poor cutting edge quality, and chip stacking in the process of processing circuit boards, resulting in burrs in the finished product, reducing costs for customers. In the case of normal wear, the V-CUT tool must be ground by 0.25mm to 0.35mm each time, that is, the diameter is reduced by 0.5mm to 0.7mm. When a new tool is worn and the gap is not greater than 0.35mm, the number of times of grinding is about 5 times.

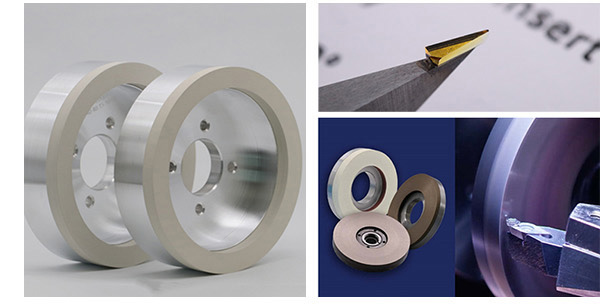

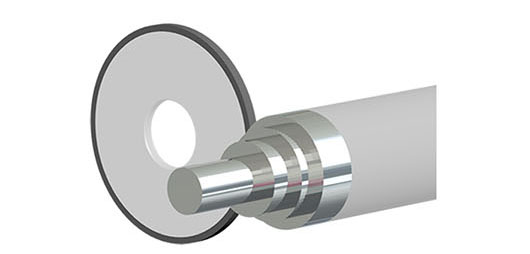

- Diamond wheel for grinding single crystal diamond tools

- According to the performance characteristics of diamond single crystal knives and the quality requirements after processing, the R&D department of Bolairong strictly screened and controlled the crystal form and grade of diamond, improved the formula, adjusted the production process, and carried out many grinding experiments. , developed rough grinding, semi-finishing, fine grinding, ultra-fine grinding vitrified bond and metal bond diamond grinding wheel with high stability and guaranteed grinding edge quality. Professionally solve the grinding problems of high grinding efficiency, good retention, no edge chipping, stable sharpening quality, ensuring the precision of the cutting edge arc and the durability and durability of single crystal knives.

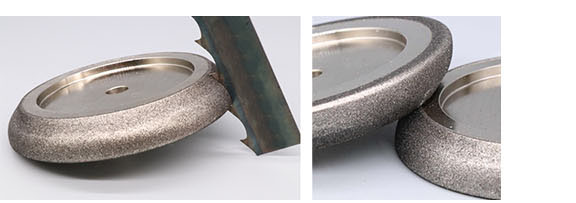

- Ceramic Diamond Grinding Wheel Dressing High Precision Roller

- It is used for grinding and dressing of high-precision electroplated diamond/CBN grinding wheels, electroplated diamond rollers, diamond sintered rollers, PCD/CBN/MCD tools, diamond grinding wheels, wear-resistant parts and various diamond tools.

- Supporting special grinding machine:

WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

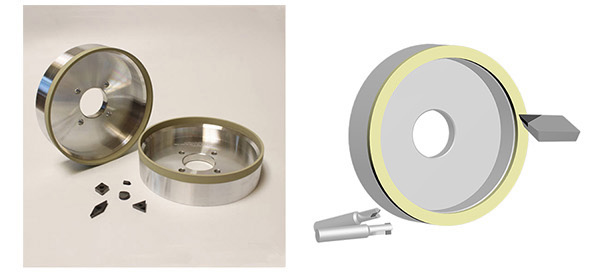

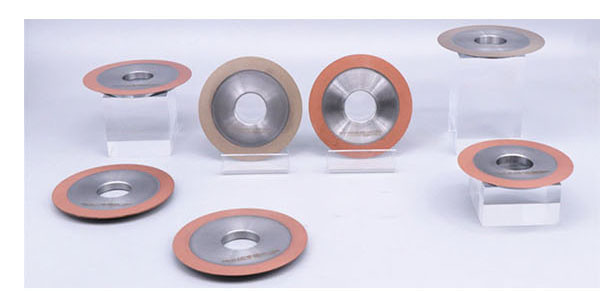

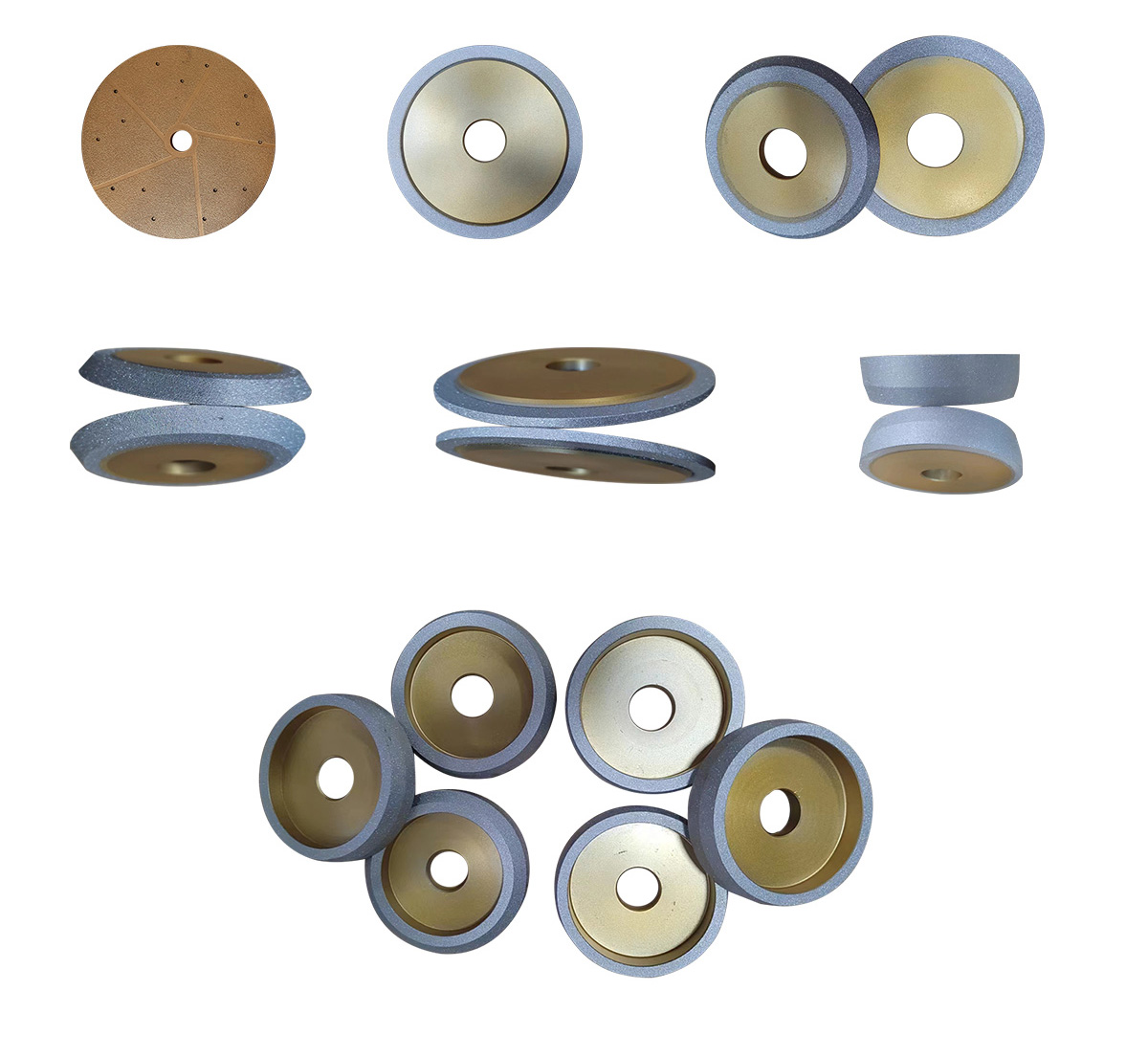

- Ceramic diamond grinding wheel for PCD/PCBN

- Bo Lai Rong Superhard Materials Co., Ltd. is committed to providing efficient and economical tool grinding solutions. Ceramic diamond grinding wheels for grinding PCD, PCBN, CVD, MCD, milling cutters, reamers, drills, regrinding, carbide, etc.

- Ceramic diamond grinding wheel size selection

• W40(500# D35) W28(D20) Coarse grinding

• W20 (800# -1000#, D20) semi-coarse grinding

• W10 (1500# D15A) W7 (2000# D15B) Fine grinding

• W5 (3000# D7) W3.5 (4000# D3) D1 (10000#) Superfinishing

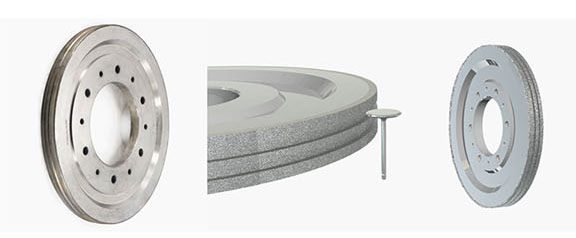

- Ceramic peripheral grinding wheels for indexable tools

- Applicable grinding machines for peripheral grinding wheels:

We can produce various types of grinding wheels, which can be matched with grinding machines, such as WENDT in Germany, WAIDA in Japan, AGATHON in Switzerland, Peripheral grinding machines produced by Swiss EWAG, British COBORN and related domestic manufacturers.

- Agathon:

400 Series: 400 PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T B, 350COMBI

250 series: PA250

Want:

400 series: WAC715, WAC735

350 series: WAM336

Vajda:

AP460E

- Suitable for grinding the peripheral plane, arc and relief angle of cemented carbide, cermet, PCD, CBN indexable inserts.

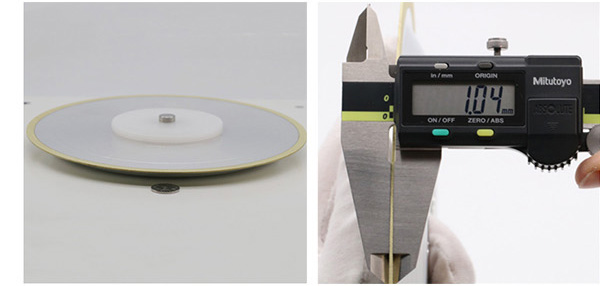

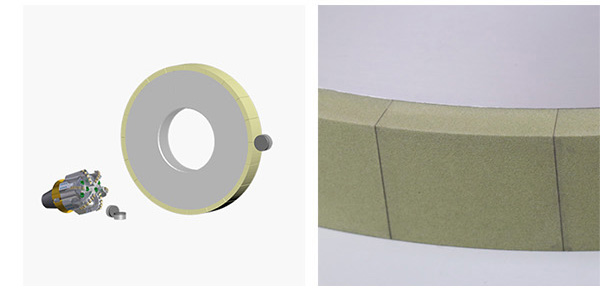

- Ceramic diamond grinding wheel for cylindrical grinding of PDC compacts

- Ceramic parallel diamond grinding wheel is mainly used for PDC cylindrical grinding.

- Vitrified Diamond Cylindrical Grinding Wheels (PDC Cutter) for Rough Grinding of Polycrystalline Diamond Blank Cylinders. Compared to resin diamond grinding wheels, our grinding wheels reduce grinding costs by 35%, save grinding time by 40% per PDC, and improve the dimensional accuracy of PDC

- Diamond CBN Ceramic Double End Grinding Disc

- Application: Ceramic diamond grinding discs are mainly used in automobile engine parts, air conditioning compressor parts, carbide tools, PCD, PCBN tools, precision bearings, hydraulic parts, pneumatic components, measuring tools, crystal gems, glass, ceramics , silicon wafer, alumina and other non-metallic materials, grinding of both end faces

- Ceramic CBN Internal Grinding Wheel

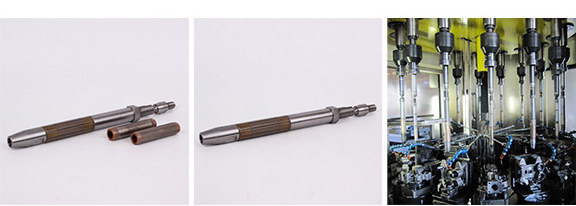

- Application: used for internal grinding of bearings, compressors, CVJ ball carriers, hydraulic tappets, universal joints, stators, rotors

Grinding of connecting rod ends in the automotive industry.

Grinding of hydraulic and pneumatic cylinders.

CVJ ball cage, inner and outer raceways.

Automotive motor hydraulic tappet.

Grind the inner ring hole.

Grind gear holes, collect.

Auto pump stator, barrel grinding.

Rollers, cylinders, flange covers of air-conditioning compressors.

Grinding of inner and outer surfaces of ball and roller bearings. Supporting high-precision imported and domestic CNC CBN internal grinding machines

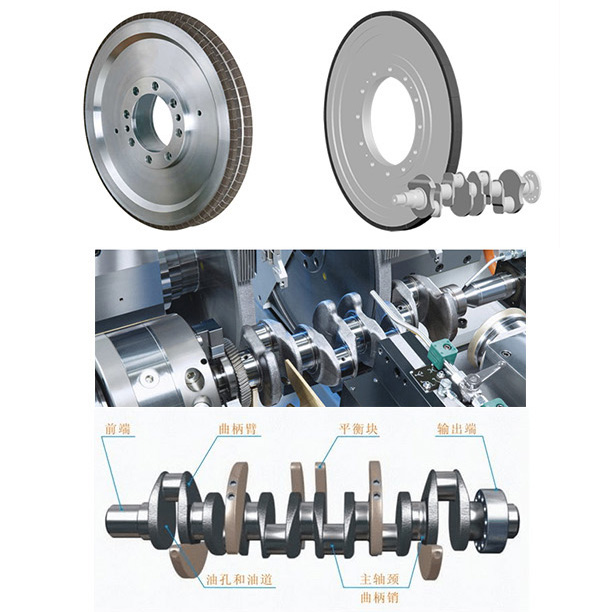

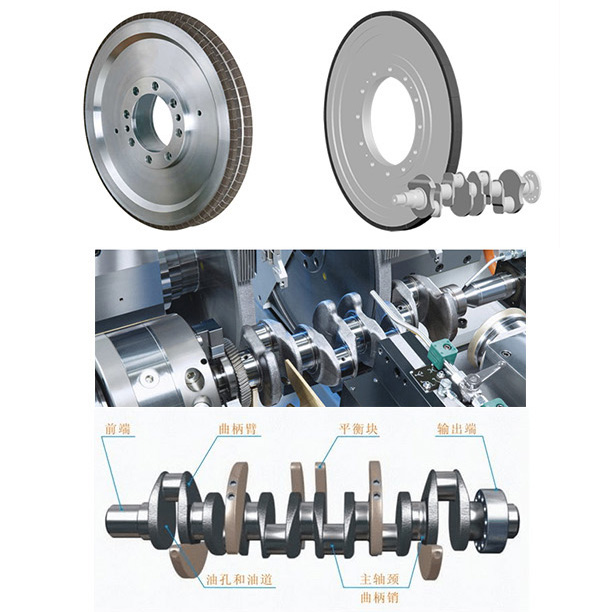

- Ceramic CBN grinding wheel for crankshaft grinding

- The crankshaft is the most important part of an engine. It bears the force from the connecting rod and converts it into torque, which is output through the crankshaft and drives other accessories on the engine to work. The crankshaft is subjected to the combined action of the centrifugal force of the rotating mass, the periodically changing gas inertial force and the reciprocating inertial force, so that the crankshaft is subjected to the bending and torsional load. Therefore, the crankshaft is required to have sufficient strength and stiffness, and the journal surface needs to be wear-resistant, work evenly, and have good balance.

- An innovation in crankshaft grinding wheels that found its use in various automotive, truck, diesel, aircraft, and small engine manufacturing, and also in various engine rebuild companies, for regrinding pins and bearings.

Grinding and regrinding of major components of crankshafts, including

• Main Bearing

• Hose/Crankpin

• Flywheel Flange End

- Supporting: Junker, Naxas, Landis, Schandt, Toyota, Toyama NTG and other grinding machines.

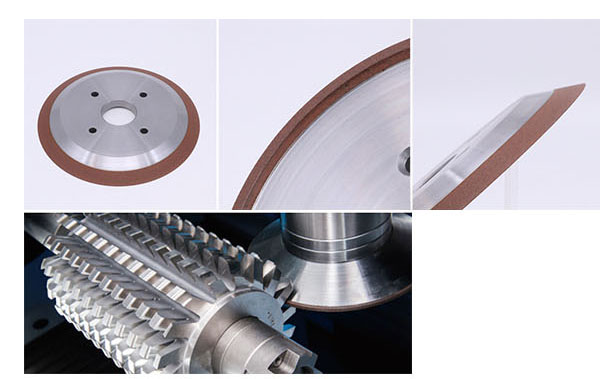

- Camshaft Grinding-Ceramic Bond

- CBN grinding wheel with vitrified bond is suitable for grinding the cam lugs of automobile camshafts.

Wheel speed 80m/s-160m/s, suitable for Toyoda, Schaudt, Landis, Junker and other CNC cam grinders.

The grinding and regrinding of camshafts mainly includes

Camshaft Spindle

• Cam (fixed on shaft)

• Cam (Single)

• Camshaft Tubes

Can be customized according to customer requirements